AeroGenie — Your Intelligent Copilot.

Aircraft Part Shipping Strategies That Work for Your Business

September 01, 2025

From urgent AOG shipments to oversized engine freight, better aircraft part shipping strategy matters. Learn the most effective ways to move high-value aviation parts safely, quickly, and cost-efficiently.

Shipping aircraft parts isn’t like shipping t-shirts or backpacks. Aircraft parts are highly specialized, often fragile, and frequently urgent items to keep operations running on time.

One delayed or damaged shipment can ground an aircraft, disrupt a maintenance schedule, or even halt an entire supply chain. Whether you’re moving avionics overseas or a sensor across the state, deploying the best shipping strategy is essential.

In this article, we’ll explore the core methods used for shipping aircraft parts, weigh the trade-offs between speed and cost, and examine the evolving infrastructure and supply chain innovations changing the future of aviation logistics. This guide is designed to help MRO firms, fleet operators, and manufacturers make smarter, more cost-efficient shipping decisions.

Why shipping aircraft parts requires specialized strategies

Aircraft parts are high stakes. An aircraft can’t take off without a functioning sensor, brake assembly, or hydraulic valve, but shipping each of these parts requires a very different approach as these are not run-of-the-mill commercial goods. The stakes are higher, and the margin for error is smaller.

One of the most high-pressure scenarios is when an aircraft is grounded due to a missing or malfunctioning part—a situation known as an AoG (Aircraft on Ground) event. In these cases, every minute counts, and airlines may pay a premium for immediate shipping via the next available flight or even a chartered plane.

Beyond urgency, parts often require careful handling due to size, weight, or storage requirements. A single part might be worth millions of dollars, and require shipment in specifically controlled settings. High-value parts often travel with IoT (Internet of Things) devices and GPS tracking for real-time monitoring, and many suppliers only work with trusted brokers or freight forwarders who are familiar with aviation protocols (AeroTime).

Four core aircraft part shipping methods

When it comes to shipping aircraft parts, the best method depends on urgency, size, value, and destination. Each strategy has its place in the aviation logistics playbook. Here are the four most common shipping methods and the scenario in which each one makes sense.

AOG shipping

Aircraft-on-ground (AoG) shipments are the go-to method when speed trumps cost. An aircraft waiting on the tarmac for a replacement part is costing money every minute, so airlines often use brokers to arrange for the fastest possible transport—typically through a “next flight out” service or even a dedicated charter flight (AeroTime). These shipments come with steep costs but are justified when getting an aircraft back in the air offsets revenue loss and operational delays.

Routine small parcel shipments

These shipments cover aircraft parts weighing under 150 lbs (68 kg), such as avionics components, sensors, or replacement panels. They often travel on scheduled passenger flights as regular freight. The process is straightforward and cost-effective for non-urgent deliveries, although it may involve multiple stops and customs processing (AeroTime).

Heavy freight shipments

For engines, landing gear, and APUs (Auxiliary Power Units), shipping gets more complex. Parts over 150 lbs are considered oversized freight and require special handling, packaging, and routing. This type of shipment might be facilitated with a dedicated cargo airline or by sea, if time permits. Transit times can stretch from days to weeks, and costs reflect the size and complexity of the goods.

High-value shipments

Aircraft parts are notoriously expensive—even small ones. For these, security is everything. Shippers often use GPS-enabled trackers, secure packaging, and tightly vetted logistics partners.

Sometimes, a human companion is even required. Some aircraft parts are so valuable, sensitive, or mission-critical that they require an escort known as an onboard courier (OBC).

These couriers personally accompany high-value shipments, such as engines, avionics, or time-sensitive components needed for AOG (Aircraft on Ground) situations, to ensure chain of custody, avoid delays, and minimize the risk of damage or theft.

This hand-carry method is often used when downtime costs or security risks outweigh traditional shipping concerns. Specialized companies provide OBC services for speed, security, and full visibility. This “door-to-door service” can also facilitate customs clearance (DHL Discover).

Air freight options

For some aircraft components, air freight is the preferred choice. It minimizes downtime and slashes carrying costs by keeping inventory levels low (CH Robinson).

There are several air freight options to choose from.

Next flight out (NFO)

NFO is the fastest and most expensive air freight option. It’s exactly what it sounds like. Your shipment is placed on the next available flight. This is ideal for emergency parts that need to reach their destination within hours (CH Robinson).

Consolidated air freight

If you can wait a bit longer, consolidated shipping groups your cargo with other orders heading to the same destination. This can significantly reduce cost while still using air freight’s speed. There is a tradeoff however; you may need to work with larger providers who have regular schedules and the volume to support it (CH Robinson).

Deferred air freight

For non-urgent shipments, deferred service is the most budget-friendly option. It typically delivers within 3–5 business days, allowing providers to use available space on scheduled flights at lower rates (CH Robinson).

Air charter services

If your part is oversized, ultra-sensitive, or bound for a remote location, a charter flight may be the best fit. This exclusive option gives you full control over timing and handling, but it comes at a premium.

Building resilient aviation supply chains

Speed and reliability for aircraft parts shipping come from selecting the right freight method and maintaining a resilient supply chain. Since the pandemic, aerospace manufacturers and suppliers have faced persistent supply disruptions, talent shortages, and geopolitical instability (McKinsey).

Use data and analytics to get ahead of disruptions

Leading aerospace firms are moving beyond reactive “control towers” and investing in early-warning systems that leverage AI and procurement data. These systems flag delivery risks before they escalate, using signals like frequent purchase order changes or anomalies in supplier lead times (McKinsey).

Improving subtier transparency is also becoming a top priority. Many OEMs now map vendors beyond tier-one suppliers to proactively manage risks in casting, forging, and chip manufacturing, as these are vital components that can halt production if delayed (McKinsey).

Encourage cross-functional collaboration

Supply chain, manufacturing, and planning teams need to share real-time data in order to prevent bottlenecks. One U.S. defense company improved throughput by 50% simply by using a cross-functional “obeya” or war-room model, aligning procurement with production to manage shortages more effectively (McKinsey).

Invest in workforce capability and root-cause analysis

Many logistics teams rely on Band-Aid fixes to shortages and delays. Training staff in root-cause analysis (RCA) allows companies to solve problems permanently, not just patch them. One aerospace firm saw part shortages drop by 30% after emphasizing RCA training (McKinsey).

And with retirements rising and digital demands growing, recruitment and upskilling efforts are more important than ever.

Airport and infrastructure considerations

Even the best shipping strategy can be undermined if the airport infrastructure isn’t built for speed, scale, or modern logistics. Efficient movement of aircraft parts often depends on ramp access, warehousing, customs clearance, and regional connectivity. Unfortunately, many regional airports underestimate just how much this matters and lose cargo volume as a result (Airports Council International).

Why some airports are skipped entirely

Freight forwarders and shippers often bypass local airports in favor of larger gateways. They prioritize direct lift capacity, larger cargo-friendly aircraft, and strategic location. Cost savings and faster processing times at larger airports can outweigh the convenience of local options (Airports Council International).

Essential factors for airport shipping success

To attract and retain aviation shipping business, airports must offer:

- Reliable roadway access for trucking

- Ample warehouse and cargo-handling space

- Customs and inspection services on-site

- Efficient ramp access and apron parking

- Modern infrastructure that supports temperature-sensitive, high-value, or oversized shipments

Kia Motors chose to build a manufacturing plant near Atlanta’s Hartsfield-Jackson airport in part due to its proximity to strong air cargo operations. This resulted in a $4 billion in economic win for the region and new, all-cargo service from Korean Airlines and Asiana Airlines (Airports Council International).

As demand for e-commerce and just-in-time (JIT) manufacturing grows, the right airports are an important component of aircraft part shipping strategies.

Partnering with the right players

Even with the best shipping strategy and infrastructure, execution often hinges on the strength of your logistics partners. In aviation, that usually means working with experienced freight forwarders, shipping brokers, and cargo airlines.

Freight forwarders

Freight forwarders are deeply involved in assembling consolidated shipments, managing customs documentation, booking cargo space, and coordinating last-mile delivery. In international aviation logistics, a good forwarder is often your lifeline to consistent, compliant, and cost-effective shipping (Airports Council International).

A case for trusted relationships

Jevgenijus Petronis, head of product at Locatory.com—a leading online aircraft parts marketplace and member of Avia Solutions Group—emphasizes that high-value shipments hinge more on trust than timelines. “With this type of high-value shipment, the question is not how much it will cost or how long it will take, but rather do you trust the people who are carrying it?” (AeroTime).

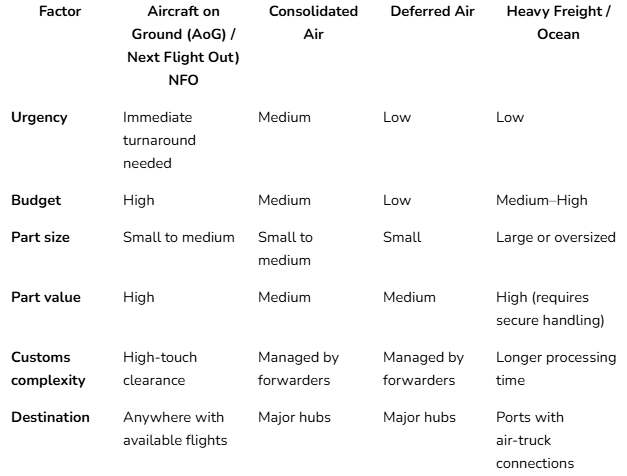

Choosing the right strategy for your needs

While some options are more secure or cost-efficient than others, aviation companies need a blended approach with different delivery options depending on priorities, constraints, and what’s at stake.

Here’s a breakdown of key factors to consider when selecting your shipping method:

For example:

- Need a fuel pump across the globe by tomorrow? AOG/NFO is your best bet.

- Replacing non-urgent cabin parts for upcoming maintenance? Consider deferred or consolidated air freight.

- Shipping an entire engine assembly? A specialized heavy freight solution, possibly by sea or chartered air, may be needed.

When you align your shipping method with your operational goals, you reduce risk and boost efficiency,

FAQs

What does an Onboard Courier (OBC) do?

An Onboard Courier (OBC) is a logistics professional who hand-carries urgent shipments on commercial flights to ensure they arrive quickly, safely, and with minimal risk. These couriers are typically used when standard freight options aren’t fast or secure enough—think grounded aircraft waiting on a single critical part, or sensitive legal and medical documents that require a trusted chain of custody.

OBCs personally accompany the package through every step of the journey, from pickup to delivery, including navigating customs and airport security, and maintaining control of the shipment at all times.

Because of their hands-on approach, OBCs are often called in for high-value, time-critical shipments where even small delays could cause significant disruption. They're trained to work across borders, fast-track customs clearance, and adapt to changing flight schedules to ensure the item arrives on time. They are commonly used in other industries beyond aerospace, including health care, pharmaceuticals, and tech.

What’s the difference between a carrier and a courier?

In aerospace logistics, the key difference between a carrier and a courier lies in the size, urgency, and handling requirements of the shipment.

Carriers are responsible for transporting large volumes of goods—such as raw materials, engine components, or aircraft structures—over long distances via air, sea, or land. They’re a cost-effective solution for bulk shipments but often come with longer transit times and less flexibility. Airlines, shipping lines, and trucking companies all function as carriers within the aerospace supply chain.

Couriers, on the other hand, specialize in delivering smaller, high-priority items—like turbine blades, avionics, or critical test documents—that require fast turnaround, secure handling, or special tracking. These services typically offer same-day or next-day delivery and are essential during aircraft-on-ground (AOG) situations or tight production schedules. Couriers can be more expensive per shipment but offer speed and precision that bulk carriers can’t match.

Companies that provide both carrier and courier services:

- DHL: Offers express courier services (DHL Express) and freight forwarding via air, ocean, and road (DHL Global Forwarding, DHL Freight).

- FedEx: Provides courier services (FedEx Express) and freight solutions for large, heavy cargo (FedEx Freight, FedEx Logistics).

- UPS: Handles small parcels and urgent courier shipments (UPS Express) and large freight (UPS Freight, now part of TFI International).

- SF Express (China): Offers both last-mile courier delivery and international freight forwarding.

- DB Schenker: Offers integrated logistics, including small parcel courier options and large-scale freight forwarding.

Companies that are carriers only

These companies specialize in moving large freight—by air, sea, or land—and do not provide courier-style services:

- Maersk: Ocean freight carrier, mainly handling containers and bulk shipping.

- CMA CGM: Major ocean freight carrier with a focus on global trade lanes.

- Nippon Cargo Airlines (NCA): Air cargo carrier moving bulk shipments.

- BNSF Railway: U.S. rail freight company transporting bulk goods.

- Atlas Air: Operates freighters for large-volume air cargo transport.

Companies that are couriers only

These focus exclusively on urgent, small, high-value shipments, especially in aerospace, medical, and legal industries:

- time:matters: Lufthansa-owned urgent logistics specialist (OBC, same-day courier).

- Wings on Board: Onboard courier (OBC) provider specializing in critical, hand-carry logistics.

- Swiss WorldCargo Courier: Handles express cargo services, often in tandem with scheduled passenger flights.

- Jetpak: Scandinavian courier specializing in urgent logistics across Europe.

- World Courier: Focuses on healthcare and pharmaceutical courier logistics (subsidiary of Cencora).

Bottom line: Smart shipping is strategic shipping

To keep planes in the air, a range of smart carrier and courier shipping strategies—inluding air, sea, and land—are a must.

From AOG emergencies to routine restocks, the ability to move aircraft parts quickly, safely, and efficiently can spell the difference between operational uptime and grounded losses.

There’s no one right method; rather, it’s about finding the best option at the time for current business needs, with choices ranging from next-flight-out services to consolidated freight options to onboard couriers (OBCs) for highly sensitive shipments like multi-million dollar engines.

By aligning with trusted logistics partners, using data to anticipate risk, and factoring in airport infrastructure and forwarder expertise, aviation companies can stay agile in an unforgiving industry marked by tight margins and complex supply chains.

Now’s the time to revisit your aircraft part shipping strategy and ask if it is as optimized as it could be for today’s demands and tomorrow’s disruptions.

ePlaneAI helps aviation businesses make better logistics decisions. Whether you're dealing with AOG events, high-value components, or complex freight moves, we’ll help you align every shipment with operational priorities.

Talk to us today about optimizing your logistics pipeline.

Aviation Maintenance Trends That May Gain Momentum in Uncertain Circumstances

Aircraft are staying in service longer, supply chains are a powder keg, and the tech is evolving overnight. Discover the maintenance trends gaining momentum and what they mean for operators trying to stay airborne and profitable.

February 2, 2026

ePlane AI at Aircraft IT Americas 2026: Why Aviation‑Native AI Is Becoming the New Operational Advantage

The aviation industry is entering a new phase where operational performance depends not just on digital tools, but on intelligence.

October 2, 2025

Choosing the Right Aircraft Parts with Damage Tolerance Analysis

The future of aviation safety is all about the parts. Authentic, traceable parts bring optimal damage tolerance and performance to fleets for maximum safety and procurement efficiency.

September 30, 2025

How to Enter New Aviation Markets: The Complete Guide for Parts Suppliers

Breaking into new aviation markets? Learn how suppliers can analyze demand, manage PMA parts, and build airline trust. A complete guide for global growth.