AeroGenie — Your Intelligent Copilot.

Inventory AI. Predict Every Aviation Part Need.

June 14, 2025

Data Engineering and Preparation for Inventory AI

Effective Inventory AI starts with a robust data pipeline. All relevant data from enterprise systems and external sources must be aggregated, cleaned, and transformed for AI consumption. This includes inventory data (historical sales, current stock levels, part attributes) and demand drivers (market trends, maintenance schedules, promotions, etc.) . By integrating internal ERP records with external factors (e.g. industry trends or seasonal patterns), the model gains a comprehensive view of demand influencers . Key steps in the data pipeline typically include:

- Data Extraction & Integration: Pull data from ERP systems (e.g. SAP, Oracle, Quantum) and other sources (supplier databases, market feeds). The platform supports automated connectors to various aviation systems, ensuring smooth data inflow . For example, historical usage, lead times, and open orders are merged with external data like global fleet utilization or macroeconomic indicators.

- Data Transformation & Cleaning: Once ingested, data is cleaned and standardized. This involves handling missing values, normalizing units (e.g. flight hours, cycles), and structuring data into meaningful features. Custom transformations and data warehouse automation may be applied to prepare AI-ready datasets. The goal is to create a unified data model that captures the state of inventory (on-hand quantities, locations, costs) and contextual variables (e.g. demand covariates, vendor lead times).

- Data Loading into the Cloud: The prepared data is loaded into a scalable cloud data platform. In our architecture, Snowflake is used as the central cloud data warehouse, which can ingest batch or real-time streams and handle large volumes of transactional data. Snowflake’s instant elasticity allows scaling storage and compute on-demand, so even massive ERP datasets and forecasting features are processed efficiently . This cloud-based repository serves as the single source of truth for all downstream analytics and machine learning.

- Business-Specific Fine-Tuning: A crucial preparation step is aligning the data and model parameters with each aviation business’s nuances. Every airline or MRO may have unique consumption patterns, lead-time constraints, and service level targets. The Inventory AI system “fine-tunes” its models to the client’s historical data and business rules, effectively learning the organization’s demand rhythms and inventory policies. This could involve calibrating forecasting models with a subset of the company’s data or adjusting optimization constraints (like minimum stocking levels for critical AOG parts). By tailoring the AI to the business, the predictions and recommendations become far more accurate and relevant to that client’s operations.

Continuous Data Updates: Inventory AI is not a one-off analysis – it continuously learns. Data pipelines are scheduled to update frequently (e.g. daily or hourly), feeding new transactions (sales, shipments, RFQs, etc.) into the model. This ensures the AI always bases decisions on the latest state of the inventory and demand. Automated data quality checks and monitoring are in place to catch anomalies in the input data, so that garbage data doesn’t lead to bad predictions. In summary, a solid foundation of integrated, clean data in the cloud enables the AI models to perform optimally and adapt to changes over time.

Machine Learning Models and Continuous Optimization

Once the data pipeline is established, advanced machine learning algorithms are applied to generate forecasts and optimization insights . The system employs a combination of models, each addressing a facet of inventory management, and it continuously improves these models as new data arrives (autonomous learning). Major components of our ML approach include:

- Demand Forecasting Algorithms: To predict future parts demand, time-series and regression models are used in tandem. For example, ARIMA (AutoRegressive Integrated Moving Average) is well-suited for capturing historical demand trends and seasonality . ARIMA helps project usage patterns for high-turnover parts, anticipating spikes or slowdowns based on past behavior . For more complex, multi-factor demand patterns, ensemble tree-based models like XGBoost come into play. XGBoost can handle non-linear interactions (e.g. the effect of weather or special maintenance events on part usage) and has proven effective for multi-variable forecasting . These forecasting models are trained on the historical sales/usage data (from the airline or MRO’s ERP), combined with external demand drivers, to predict short-term and long-term requirements for each part number. The AI continuously retrains or fine-tunes these models as fresh data arrives, improving accuracy over time (the auto-learning capability).

- Inventory Optimization Models: Beyond predicting demand, the system optimizes stock levels and reorder policies. A Random Forest model is utilized to recommend optimal inventory levels by analyzing a multitude of factors simultaneously . This model can evaluate part criticality, lead time variability, holding cost, and usage frequency to determine how much of each item should be kept on hand. By learning from historical stockouts and overstock situations, it identifies the sweet spot that minimizes both shortage risk and excess stock. In practice, Random Forest-based predictions have helped reduce forecasting error and inventory costs – for instance, studies found this approach improved spare part stock level prediction accuracy by ~25% in similar supply chain challenges . The AI also leverages optimization algorithms (potentially linear programming or stochastic optimization) to compute reorder points and order quantities. It automatically calculates the ideal reorder point for each part, factoring in the forecasted demand during lead time, desired service level, and variability . When stock on hand hits these AI-derived reorder points, the system can trigger replenishment actions (either alerting a planner or auto-generating an order), thereby implementing auto-optimization of reorders. This closed-loop optimization continuously adjusts to demand trends – if a part’s usage increases, the reorder point and safety stock are raised accordingly; if demand wanes, the system pulls back to avoid overstock.

- Dynamic Pricing and Excess Stock Reduction: Inventory AI not only helps with buying parts but also with selling or redistributing excess inventory. The platform includes dynamic pricing models that analyze market data (e.g. recent sale prices on marketplaces, supply vs. demand) to recommend optimal pricing for parts. Using machine learning (such as gradient boosting or even neural networks), it evaluates how pricing a part at various levels might affect its sell-through rate. For example, the system might observe that a certain avionics component is in surplus internally but in short supply globally – it will suggest a competitive selling price that maximizes margin while likely securing a buyer. By analyzing market trends, the AI can generate suggested prices for both procurement and sale of parts . This helps sales teams avoid underpricing valuable stock or overpaying for new procurement. The pricing model continuously updates with new market information, learning the price elasticity for different part categories. Combined with demand forecasts, this enables truly dynamic, market-aware pricing strategies in the aviation parts market.

- Vendor Performance and Lead Time Prediction: Another critical ML aspect is analyzing vendor performance data to inform inventory decisions. The system tracks supplier metrics such as on-time delivery rate, quality issue frequency, lead time consistency, and price competitiveness. AI models (including classification or anomaly detection algorithms) process these historical vendor records to predict future reliability and flag potential risks . For instance, if a certain vendor’s deliveries have been slipping, the model might proactively recommend increasing safety stock for parts sourced from that vendor (or suggest alternate suppliers). Key supplier performance indicators – delivery performance, quality compliance, cost efficiency, and responsiveness – are continuously monitored by the AI . Patterns like a trend of late shipments or increasing defect rates can be detected early by the ML, which then alerts procurement to mitigate the issue (e.g. by diversifying sources or expediting orders) . This predictive vendor analysis is crucial in aviation where lead times for parts can be long and any disruption can ground aircraft. By forecasting supplier performance, the inventory system optimizes reorder timing and quantities – for example, ordering earlier or extra quantity if a supplier is likely to be late. Overall, these AI-driven insights on vendors enhance the resilience of the supply chain.

- Continuous Learning and Auto-Optimization: All the models above operate in a feedback loop of continuous improvement. As more data is collected (new sales, updated lead times, realized demand vs. forecast, etc.), the AI refines its predictions. The platform’s continuous improvement mechanism uses ML to adapt and refine processes over time . The demand forecasting models get recalibrated with the latest actuals (reducing error going forward), and the inventory policy rules are auto-adjusted based on what’s working or not. This auto-learning ensures the system doesn’t grow stale – it evolves with changing usage patterns (for instance, if a new aircraft model enters service and drives new parts consumption, the AI will learn its impact). Additionally, an AutoML approach is leveraged to periodically test new algorithms or hyperparameters, ensuring that the best performing modeling technique is used for each prediction task. In essence, the machine learning layer is not static; it is an ever-improving brain of the inventory system, leading to higher accuracy and smarter optimization decisions over time. This continuous ML optimization, paired with domain expertise, is what allows Inventory AI to reliably cut inventory costs and improve service levels by a significant margin. (In fact, AI-driven inventory optimization in aviation has been shown to reduce inventory costs by up to ~37% while improving operational efficiency by 60%+ through better forecasting and automation .)

Cloud-Based Architecture with Qlik and Snowflake

Modern Inventory AI solutions are built on a cloud computing architecture, which provides the scalability, integration, and performance needed for real-time analytics. Our system is 100% cloud-based, leveraging Snowflake’s Data Cloud and Qlik’s analytics platform in the backend. This architecture ensures that all computations and data storage happen in the cloud (no on-premise servers required), so global teams can access the tools anywhere and the system can scale to any data volume or number of users.

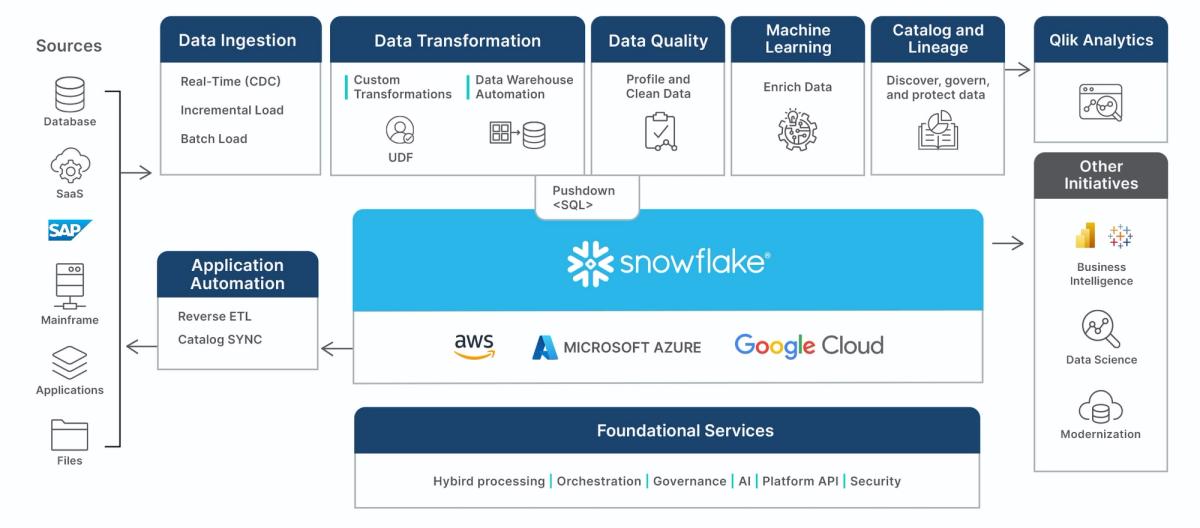

Figure: High-level architecture integrating diverse data sources with a Snowflake cloud data platform, feeding into machine learning and analytics. Data is ingested (batch or real-time) from ERP databases, SaaS applications, and files, then transformed and stored in Snowflake’s cloud data warehouse. The platform handles data quality, machine learning model execution, and provides cataloging/governance. Qlik’s analytics layer sits on top, delivering interactive dashboards and AI-driven insights to end-users .

Snowflake as the Data Backbone: All enterprise data is consolidated in Snowflake, a cloud-native data warehouse known for its high performance and elasticity. Snowflake stores the cleaned ERP data, inventory records, and any external datasets in a centralized manner. Because Snowflake is a fully-managed cloud service, it can automatically scale up or down based on workload, allowing us to run intensive ML computations or complex queries on demand without worrying about infrastructure . This elasticity is crucial when forecasting thousands of part numbers or running simulations – the system can spin up extra compute power in the cloud to handle the load, then scale back. Snowflake also offers secure data sharing and integration capabilities, which we use to pull data from various sources and even share certain results with partners as needed, all while maintaining strict security (SOC 2 and ISO 27001 compliance for data protection is supported ). By using Snowflake, our Inventory AI platform can handle big data volumes (e.g. years of transaction history, millions of parts records) and perform near-real-time updates. The cloud data warehouse approach frees clients from managing databases and provides a single source of truth that is accessible by all other components (the ML engines, the dashboard, and even client’s other BI tools if needed).

AI Processing and Scalability: The machine learning components of Inventory AI are also deployed in the cloud environment. For maximum scalability and reliability, the predictive models and optimization routines are hosted on cloud compute services (for example, using AWS Lambda or cloud VMs) . This means that whenever the system needs to generate a new forecast or recommendation, it can invoke cloud functions that run the ML models against the latest Snowflake data. Deploying the AI in cloud ensures that computationally heavy tasks (like training a new model or evaluating thousands of scenarios) run efficiently and can be parallelized. There is no single point of failure; the architecture can tolerate outages by rerouting to other cloud resources or zones. Additionally, cloud deployment facilitates continuous delivery of updates – new model improvements or feature enhancements can be rolled out seamlessly to all users without local installs. The end result is real-time or on-demand analysis capabilities: users always see up-to-date predictions on the dashboard, and they can trust that behind the scenes the AI is crunching the very latest data. As one example, an aviation parts distributor can have the AI re-run forecasts immediately after uploading last month’s sales data – the cloud functions will execute the updated prediction and refresh the dashboard within minutes, thanks to the on-demand scalability of the cloud. As noted, “deploying in the cloud allows distributors to access real-time insights anytime” and scale as needed to meet demand spikes.

Interactive Dashboard with Qlik: On the front-end, Inventory AI provides a custom AI dashboard powered by Qlik, a leading analytics and business intelligence tool. Qlik is connected directly to the Snowflake data warehouse, enabling it to query the latest data and model outputs with high performance. The use of Qlik brings rich interactive visualization and analysis capabilities to the end-user. We have built a variety of dashboard views and charts (inventory trends, forecast vs actual, stock distribution, performance KPIs, etc.) using Qlik’s analytics engine. The AI insights are embedded into these dashboards – for example, the system might highlight parts that are predicted to stockout in the next 30 days, flag excess stock items, or show vendor performance scores, all in an interactive interface where users can filter by aircraft fleet, location, time frame, and so on. Qlik’s integration with Snowflake is optimized for real-time analytics, meaning any new data loaded into Snowflake (or any new AI recommendation generated) can be instantly reflected in the dashboard . Users experience a smooth, responsive system where they can drill down into data, ask ad-hoc questions, and even use natural language queries (with AI assistance) to get answers from the inventory data. The Qlik layer also handles alerting and notifications – for instance, we configure alerts for certain conditions like “critical part below safety stock” or “forecast error above X%,” which Qlik can send out to inventory managers via email or mobile notification, ensuring nothing important is missed. In summary, Qlik serves as the user-facing intelligence portal, turning the raw predictions and numbers from the AI into intuitive charts, KPIs, and actionable dashboards for decision-makers. It bridges the gap between the complex data science in the back-end and the practical decision-making on the front-end, allowing even non-technical users (planners, buyers, sales teams) to leverage AI-driven analytics in their daily workflow .

Integration and Compatibility: Our cloud architecture is designed to plug into the existing IT landscape of aviation companies. Whether the client uses a traditional ERP (like SAP, Ramco, Amos) or has data already in a cloud lake/warehouse, our solution can integrate smoothly. The platform “works with SAP, Snowflake, Oracle, AMOS, Quantum, and other aviation systems for smooth enterprise adoption” . We provide connectors/API endpoints to ingest ERP data to Snowflake continuously, and similarly we can feed outputs (like order recommendations or pricing updates) back into the ERP or other systems. This broad compatibility means all ERP systems are supported – the AI doesn’t require replacing your ERP, it augments it by sitting on top in the cloud and reading/writing data as needed. Being cloud-based also means minimal on-premise installation; the solution can be accessed via web browser and connects securely to the data sources. Aviation firms appreciate that this architecture complies with IT security and data governance policies: data transfers are encrypted, access is controlled via roles, and the cloud environment meets industry standards. In effect, the combination of Snowflake’s secure data cloud and Qlik’s governed analytics ensures enterprise-grade security and compliance while delivering cutting-edge AI capabilities. The entire system is multi-tenant and scalable, so whether a client has one site or global sites, a few users or hundreds, the performance remains fast and reliable. By emphasizing cloud computing and a flexible integration layer, Inventory AI can be rolled out quickly and work in harmony with the tools and processes aviation companies already have in place.

Tailoring AI to Aviation: Use Cases and Industry Integration

Designing an inventory optimization AI specifically for the aviation industry means addressing the unique challenges and workflows of airlines, MROs, and aircraft parts suppliers. Our solution, therefore, is fine-tuned for aviation use cases: managing spares for aircraft fleets, supporting MRO supply chains, and enabling efficient trading of surplus parts. Below, we highlight how Inventory AI is applied in this domain, and the special features that empower both sellers and buyers (airlines, MROs, parts distributors) in the aviation space.

Demand Forecasting for Aviation Parts: Aviation spare parts demand is notoriously hard to predict – it often follows an intermittent pattern (long periods of zero usage punctuated by sudden needs, especially for critical LRUs). The AI addresses this by using sophisticated forecasting tailored to spare parts behavior. As noted in research, forecasting accuracy for spare parts is a critical factor in ensuring operational readiness and budget efficiency . Our system incorporates probabilistic models to handle intermittent demand (Croston’s method or intermittent demand Croston-based models can be integrated alongside ML models), and it leverages fleet data (e.g. aircraft flight hours, cycles, maintenance schedules) to predict when parts will be required. By achieving higher accuracy in predicting parts demand, airlines can ensure they have the right part at the right time, minimizing AOG (Aircraft on Ground) situations. One case study in military aviation showed that applying multiple AI models together improved forecasting accuracy significantly for spare parts, confirming the value of an ensemble AI approach . In practical terms, our AI might forecast the next likely failure or maintenance need for a component based on usage patterns, allowing the airline or MRO to pre-position that part. This reduces emergency orders and expedites, thus cutting costs and aircraft downtime.

Optimized Procurement & Automated RFQs: In aviation procurement, RFQ (Request for Quote) management is a daily task – buyers send out RFQs to suppliers or check parts marketplaces to find needed components. Inventory AI streamlines and automates much of this workflow. The system can automatically generate RFQs or purchase requests when certain conditions are met (e.g. stock falls below the AI-calculated reorder point, or a forecast signals a future shortfall). These RFQs are populated with the part details, required quantity, need-by date, and even a suggested target price as determined by the AI’s pricing model. By automating RFQ creation and even response parsing, the platform “automates RFQs, quotes, and procurement workflows to save hours daily” . For example, if an airline is short on a specific avionics unit, the AI might identify approved vendors for that unit, draft an RFQ message, and send it via email or marketplace API. When vendors respond with quotes, the AI (with the help of natural language processing from our Email AI module) can parse the replies, compare prices and delivery dates, and recommend the best option to the human buyer. In many cases, routine purchases of common parts can be fully automated – the system will choose the optimal quote based on vendor performance and price, then trigger a purchase order in the ERP, all without manual intervention. This level of automation not only speeds up the supply chain (critical when maintenance schedules are tight) but also ensures procurement decisions are data-driven. Every RFQ and quote received further enriches the data, which the AI uses to learn pricing trends and supplier behavior, continually improving its recommendations.

Three-Click Buying and Selling (Marketplace Integration): A standout feature of our aviation-focused Inventory AI is the seamless integration with industry marketplaces like ILS (Inventory Locator Service) and PartsBase. These online platforms are where aviation companies buy and sell spare parts globally. We’ve integrated their APIs directly into the Inventory AI dashboard, enabling users to execute marketplace actions in just a few clicks. The system identifies surplus or slow-moving stock in your inventory – parts that are not needed in the foreseeable future – and can list them for sale on ILS/PartsBase almost instantly. Users can review the AI’s suggested listing (including recommended price) and then post it with, literally, three clicks. Similarly, if the AI detects a future shortage of a part, it can search the marketplace for available stock and either directly initiate a purchase or at least present the options to the user for one-click ordering. This deep integration means you “list, sync, and manage inventory across leading marketplaces without leaving the platform” . For instance, an MRO can view a dashboard of excess parts, tick the ones to sell, and the system will push those listings out to ILS and PartsBase along with all necessary details (condition, certs, etc.), saving tremendous time compared to manual listing. On the buy side, if a needed part is available on these exchanges, the system can fetch live data on price and availability. The platform may also maintain a preferred suppliers list and cross-reference marketplace vendors with known good performers. The three-click paradigm emphasizes how easy and fast this process becomes: what used to involve separate systems and manual data entry is now an integrated experience – identify a need or surplus, click to see market options, and click to confirm a transaction. This greatly boosts agility in inventory balancing, turning excess stock into cash and filling gaps proactively.

Vendor Connectivity and Performance Tracking: In the aviation supply chain, maintaining strong supplier relationships and monitoring performance is vital (delayed parts can cost airlines heavily). Inventory AI includes vendor connectivity features that allow direct integration with supplier systems and real-time performance tracking. It can connect to supplier portals or accept electronic updates, so that things like shipment tracking, delivery confirmations, and quality reports feed directly into the AI system. The platform “provides real-time vendor integration for seamless ordering” – meaning once a purchase order is placed, it continues to monitor that order’s status. If a shipment is delayed beyond the vendor’s usual lead time, the AI flags it and might recommend sourcing from backup suppliers. The system also logs every vendor transaction to build a performance profile (on-time %, average lead time vs promised, defect rate, etc.). These metrics are visible on the dashboard, giving procurement a clear view of vendor performance at a glance. For example, a widget may show that Vendor X has a 95% on-time rate and average delivery of 5 days, whereas Vendor Y is at 80% on-time and 9 days – such insights guide the buyer to favor Vendor X for critical parts. Over time, the AI’s accumulated vendor data can even predict risks: if a normally reliable vendor starts slipping, the trend is caught early. This is particularly useful for MROs managing repairs, as they often send parts to external shops; the AI can monitor those repair cycle times as well. All of this ensures that the supply side of inventory is tightly controlled and optimized – you’re not just stocking the right amount, but also getting it from the right source at the right time.

Cloud-Based Collaboration and ERP Compatibility: Since the solution is cloud-based, all stakeholders (from sales teams to buyers to inventory planners) access the same live system. An airline’s sales team can use the dashboard to identify if there are parts they can offer to the market (seeing excess stock and the AI’s suggested selling price), while the procurement team simultaneously uses it to manage incoming needs. The platform’s compatibility with all major ERPs means it fits naturally into the existing processes. For example, if using SAP, the AI can write back the optimized min/max levels or reorder points it computes into the SAP material master, effectively updating ERP planning parameters with AI insights . It can also ingest open RFQs from the ERP and automate responses. No matter which ERP or maintenance system (AMOS, TRAX, etc.) is in use, the cloud integration layer ensures data flows in and out without disruption. This flexibility is important in aviation, as many companies have legacy systems – our AI adds a modern intelligence layer on top of them without requiring a rip-and-replace. And because everything runs in the cloud, even remote teams (say, a purchasing officer at an outstation) can access the tools via web and be part of the workflow, which is a big improvement over siloed desktop tools or spreadsheets.

Managing the Complete Inventory Lifecycle: Inventory AI covers the end-to-end lifecycle of parts management in aviation. It starts with planning – forecasting demand and setting optimal stocking levels. It then informs procurement – automating RFQs, suggesting orders, and handling supplier interactions. Next, it assists in operations – monitoring stock levels in real time, triggering replenishments, and issuing alerts for anomalies (e.g. sudden demand spikes or low stock warnings) . It also aids the sales/disposition side – identifying slow-moving or obsolete stock and facilitating its sale through marketplaces or reallocation. Throughout this cycle, the AI is optimizing financial and service outcomes: reducing excess inventory (thus freeing up working capital) while also reducing stockouts (thus improving service level to maintenance operations). The system provides utilization analytics that show how inventory is being consumed or turning over , which helps pinpoint inefficiencies like parts that haven’t moved in years (candidates to sell off) or extremely high turnover parts (candidates to stock more of). Additionally, what-if analysis is available – users can simulate scenarios such as an upcoming fleet retirement or a supplier shutdown, and the AI will project the impact on inventory and recommend actions (like proactively sell the parts of retiring aircraft, or buy extra stock from alternate suppliers in case of a disruption).

Finally, the solution emphasizes ROI and results for aviation clients. By implementing Inventory AI, airlines and MROs can expect tangible improvements: lower inventory holding costs, fewer AOG incidents due to missing parts, faster quote-to-sale cycle for surplus parts, and productivity gains (since the manual drudgery of data crunching and RFQ processing is greatly reduced). In an industry where every minute an aircraft is grounded can cost tens of thousands of dollars, having an AI that optimally manages spare parts translates directly into improved uptime and cost savings. The entire platform operates in real-time and in the cloud, meaning the intelligence is always on – monitoring, predicting, and optimizing 24/7. This is the power of a tailored Inventory AI for aviation: it merges cutting-edge machine learning with industry-specific integration (ERP, ILS, PartsBase, etc.) and presents it through an easy-to-use cloud dashboard. The result is that an airline or MRO can “make faster, smarter decisions with AI-driven demand, pricing, and stock insights”, all within a unified system . By harnessing these advanced capabilities, aviation businesses can stay ahead of demand fluctuations, negotiate better with suppliers, and turn their inventory from a cost center into a competitive advantage.

Aviation Maintenance Trends That May Gain Momentum in Uncertain Circumstances

Aircraft are staying in service longer, supply chains are a powder keg, and the tech is evolving overnight. Discover the maintenance trends gaining momentum and what they mean for operators trying to stay airborne and profitable.

February 2, 2026

ePlane AI at Aircraft IT Americas 2026: Why Aviation‑Native AI Is Becoming the New Operational Advantage

The aviation industry is entering a new phase where operational performance depends not just on digital tools, but on intelligence.

October 2, 2025

Choosing the Right Aircraft Parts with Damage Tolerance Analysis

The future of aviation safety is all about the parts. Authentic, traceable parts bring optimal damage tolerance and performance to fleets for maximum safety and procurement efficiency.

September 30, 2025

How to Enter New Aviation Markets: The Complete Guide for Parts Suppliers

Breaking into new aviation markets? Learn how suppliers can analyze demand, manage PMA parts, and build airline trust. A complete guide for global growth.