AeroGenie — Your Intelligent Copilot.

How to Make Aircraft Health a Top Priority for Advanced Air Mobility

July 24, 2025

Advanced air mobility (AAM) is taking off, but battery degradation, composite stress, and frequent short-burst flights in tight areas demand smarter fleet health strategies. Discover how ePlaneAI delivers predictive insights that power AAM flights.

Advanced air mobility is here, but fleet health needs to catch up

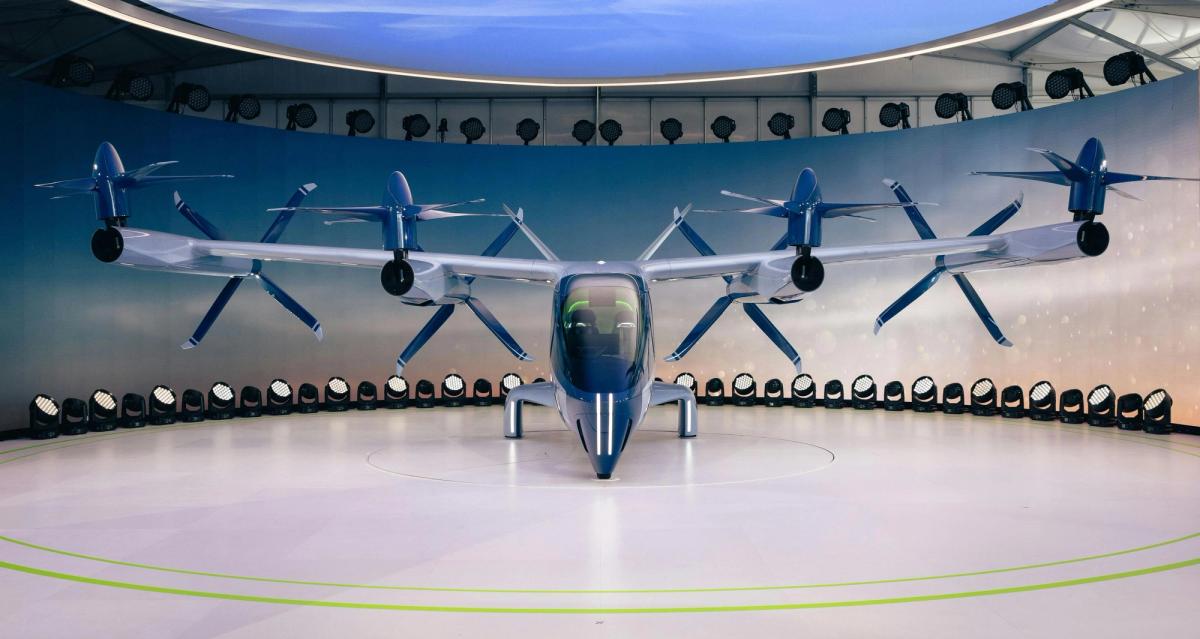

Advanced Air Mobility (AAM) aircraft is no longer a futuristic, trade-show concept.. Across the globe, startups, OEMs, and major airlines are investing heavily in urban air taxis, eVTOLs, hybrid-electric regional aircraft, and autonomous drones. The audacious aim is to create a fully scalable, highly available, safe, and efficient aerial transportation network that operates in congested urban centers and underserved regional routes.

But these platforms aren’t just smaller versions of traditional aircraft. They’re radically different machines with new propulsion technologies, lightweight composite structures, and entirely untested operational settings at commercial scale. And with those differences come heightened challenges around safety, reliability, and maintenance.

In the high-visibility world of AAM, any system failure becomes amplified. An unexpected powertrain failure on a regional jet is one thing; a battery malfunction mid-flight over downtown Chicago is something else entirely. For new aviation models to scale successfully, proactive fleet health management is everything. It’s as crucial as airworthiness certificates and pilot training.

Major airline operators and MRO leaders have already proven the power of predictive maintenance and aircraft health monitoring systems (AHMS) on large commercial fleets. Now, AAM innovators must apply and adapt those lessons for the unique realities of smaller aircraft with shorter flight cycles in denser urban areas—and entirely new failure modes.

New stakes for fleet health in the advanced air mobility market

The entire appeal of AAM rests on high utilization and flexible, on-demand operations. Unlike long-haul widebody aircraft that spend hours in the sky between maintenance windows, many AAM platforms are designed to perform dozens of short-hop missions per day. That relentless cadence has enormous revenue potential if operators can navigate the safety and MRO minefield.

Old-school maintenance models aren’t designed to service planes with high-frequency, short-haul flights. Scheduled checks based on fixed flight hours or calendar intervals, used for large passenger planes, can’t fully capture the emergent wear patterns of electric motors, composite stress points, or battery degradation profiles.

And with new mobility aircraft, fleets are held to higher standards. A single high-profile failure could erode investor confidence and public trust.

The physical demands of AAM environments add further strain:

- Distributed electric propulsion systems require constant balancing of multiple motors and rotors operating simultaneously.

- Urban vertiports expose craft to frequent short cycles, high vibration exposure, and tight turnarounds.

- Advanced composite structures may exhibit damage in ways not easily detectable via legacy inspection regimes.

- Energy storage systems (batteries, hybrid-electric powertrains, hydrogen cells) introduce thermal management and lifespan challenges with no historical commercial dataset to rely on.

At the same time, regulatory agencies, which are already cautious as they oversee AAM certification pathways, are likely to impose stricter fleet health documentation and predictive safety assurance requirements than what traditional air carriers have faced.

In short, the advanced air mobility market must build comprehensive health monitoring systems into its DNA from day one. As the market widens, there is a growing playbook to borrow from. Many large commercial operators have spent the past decade developing predictive capabilities that are already delivering significant ROI.

What aircraft health monitoring systems (AHMS) actually do

Before talking about aircraft health monitoring systems (AHMS) for advanced air mobility units, let’s define what a modern AHMS is.

While many think of them as simple onboard warning lights or periodic inspections, a mature AHMS is much more comprehensive. It turns your aircraft into a rolling data node that feeds constant information streams into centralized platforms for analysis and issue diagnosis.

AHMS generally consists of two core layers:

1. Airborne health monitoring subsystem

This is the hardware living inside the aircraft itself. Embedded sensors capture a vast array of readings in real-time during flight, including:

- Engine vibration

- Rotor speed harmonics (especially for distributed electric propulsion)

- Thermal readings across batteries and power systems

- Airframe structural loads and flex points

- Landing gear cycles

- Auxiliary power unit (APU) health

- Electrical system load balances

- Cabin environment conditions

These sensor arrays allow constant monitoring of critical systems that would otherwise require invasive manual inspections or extensive downtime.

2. Ground health diagnostics subsystem (GHMS) analytics

Once sensor readings leave the aircraft, often in real time, they enter centralized diagnostic platforms. Ground teams analyze current and historical trends to:

- Detect emerging fault patterns

- Generate predictive alerts for MRO crews

- Optimize spare parts ordering and scheduling

- Feed AI models that refine future prognostic accuracy

Some GHMS platforms now include AI-powered engines capable of cross-referencing thousands of historical flight profiles, similar aircraft systems, and known failure modes to generate high-confidence predictions about developing issues.

Together, this loop creates a powerful shift away from reactive fixes toward true predictive decision-making.

Lessons from the big airlines: How predictive maintenance is already delivering ROI

The big commercial airlines have already proven how game-changing AHMS can be, and they’re not dabbling. These systems are fully up and running today across some of the world’s most demanding fleets.

United Airlines: CHIME platform

At United Airlines, the Condition and Health Indication, Monitoring and Engineering (CHIME) platform is the engine of their predictive maintenance workflows. This centralized digital system integrates fault data from across United’s 970 mainline aircraft. CHIME can generate real-time alerts for critical subsystems like flight controls, landing gear, and electrical systems.

The results are hard to ignore:

- Over 300 major out-of-service events were prevented

- More than 1,000 flight delays or cancellations avoided

- 130,000 metric tonnes of carbon emissions saved through optimized scheduling

United’s leadership believes predictive maintenance has already shifted from “experimental technology” to core operational infrastructure.

Lufthansa Technik AVIATAR: Cross-fleet integration

Lufthansa’s AVIATAR platform takes this even further, integrating both Airbus and Boeing fleets into one unified predictive maintenance system. In collaboration with United Airlines, AVIATAR has expanded its Condition Monitoring capabilities to support Boeing 737NG and Airbus A320 fleets simultaneously, allowing MRO teams to seamlessly monitor mixed fleets.

By centralizing both condition monitoring and predictive service alerts, Lufthansa Technik and United have successfully implemented a fully comprehensive health monitoring ecosystem across different aircraft OEM platforms.

British Airways: Eliminating paper logs

British Airways has fully digitized its technical logbook systems, replacing standard paper-based logs with real-time E-Logs entered by pilots and crew directly via onboard iPads. This allows ground teams to pre-order parts, coordinate repairs while aircraft are still airborne, and dramatically reduce turnaround times.

The sustainability benefits are compelling, with over 900,000 pieces of paper eliminated annually from outdated logbook procedures.

Emirates: Skywise + Core X3 integration

Emirates recently partnered with Airbus to implement Skywise Fleet Performance+ (S.FP+), combining real-time fleet monitoring with AI-driven predictive analytics. This gives Emirates Engineering instant access to live system health data, automated pre-departure checks, predictive fault diagnostics, and connected dashboards across their Airbus A380 and A350 fleets.

Scaling predictive health into advanced air mobility: the hard parts

As promising as predictive maintenance has proven for large airline fleets, translating these systems into advanced air mobility (AAM) brings an entirely new set of challenges. The aircraft might be smaller, but the complexity of monitoring them is, in some ways, even higher.

Limited historical maintenance data

The predictive models powering commercial AHMS platforms like Lufthansa’s AVIATAR or Boeing’s Airplane Health Management rely on decades of historical flight, failure, and maintenance data, rich information logs that AAM platforms simply don’t have. Most eVTOLs, hybrid-electric aircraft, and autonomous drones are still in early certification phases, with minimal in-service experience to draw from.

Without robust historical datasets, AI-powered prognostics struggle to accurately identify failure precursors or best manage service intervals. This forces AAM operators to build large datasets in real time, during live flight service, a far riskier proposition in a high-scrutiny arena.

New materials, new failure modes

Lightweight composite airframes, hybrid propulsion units, high-density batteries, and distributed electric propulsion introduce structural and mechanical behaviors that aren’t fully understood at scale. For example:

- Microcracking in composite blades may evolve differently from metal fatigue in legacy rotors.

- Battery cell degradation requires continuous monitoring of thermal profiles, charge and discharge rates, and early swelling indicators.

- Rotor and motor harmonics introduce vibration patterns unfamiliar to most legacy vibration monitoring systems.

Sensors, analytics models, and inspection protocols must all be adapted accordingly.

Complex urban flight environments

Unlike traditional airport-to-airport routes, AAM platforms operate in tight urban corridors filled with microclimate variations, narrower airspace constraints, and a higher frequency of vertical takeoffs and landings. Each introduces unique operational stresses that existing AHMS platforms, designed around commercial long-haul cycles, aren’t calibrated to handle without major adjustments.

Immature AI training models

AI/ML tools depend entirely on the quality, consistency, and quantity of their training datasets. Without multi-year, cross-platform performance data from AAM aircraft, early-stage predictive models risk overfitting to narrow or biased sample sets or missing rare but catastrophic failure indicators.

Addressing these gaps will require collaborative industry-wide data sharing, standardization efforts, and OEM partnerships, something the commercial aviation has only recently started embracing at scale.

Technology enablers make AAM health monitoring possible

Despite the steep technical climb, a convergence of advanced technologies is now making scalable health monitoring for AAM feasible. The very same disruptive trends fueling AAM’s aircraft designs are also empowering better fleet health solutions.

Smart sensor evolution

Miniaturized, ruggedized sensors can now be embedded directly into composite structures, battery packs, and rotor components. These include:

- Fiber optic strain gauges for structural load monitoring

- Wireless accelerometers for vibration tracking

- Thermal sensors inside energy storage units

- Embedded ultrasonic sensors for internal flaw detection

Advanced sensors offer non-invasive, real-time monitoring that aligns perfectly with AAM’s mission of minimizing downtime while maximizing data fidelity.

AI-powered predictive analytics

Artificial intelligence algorithms process thousands of incoming data streams to detect subtle deviations and identify emerging fault patterns. Machine learning models constantly refine themselves as new failure cases accumulate, improving both sensitivity and specificity of predictive alerts.

Edge computing and real-time in-flight processing

Rather than waiting for post-flight analysis, edge computing systems enable real-time in-flight diagnostics. This allows autonomous or lightly-crewed AAM vehicles to:

- Detect anomalies mid-flight

- Self-adjust system loads

- Trigger automated pre-landing maintenance orders

- Inform vertiport teams of immediate service needs upon arrival

Secure data ecosystems

With AAM fleets likely operated by a mix of OEMs, operators, and third-party service providers, data integrity becomes paramount. Rolls-Royce’s early integration of blockchain into its AHMS solutions provides one model for ensuring audit-proof records of fleet health.

As regulators demand tighter oversight over upkeep practices, secure, interoperable health monitoring platforms will likely become a prerequisite for AAM certification.

The business case for early investment in health monitoring

In advanced air mobility, predictive health monitoring is a commercial survival tool. The entire AAM business model hinges on high utilization rates, minimal downtime, and public confidence in the safety of new-fangled, futurist air technology. Without robust health monitoring systems, operators face cascading risks across nearly every dimension of their operation.

1. Downtime is financial poison

A single unplanned grounding event can destroy profit margins for aircraft that rely on short-hop, high-frequency utilization. Unlike major airlines that can rotate grounded jets out of the schedule, AAM operators with smaller fleets will feel every disruption acutely. Predictive maintenance dramatically reduces the volume of these unscheduled events.

2. Investors demand reliability proof

Institutional investors entering the AAM market want more than engineering demonstrations; they want empirical proof that emerging fleets can sustain safe, reliable processes at scale. Predictive health monitoring platforms provide objective, real-world performance proof that demonstrates mission-ready maturity.

3. Certification pathways are data-driven

AAM certification will not simply mimic legacy aviation models. Regulators are increasingly evaluating ongoing performance safety data (beyond static design documentation) as part of airworthiness assurance. Continuous health monitoring platforms may become essential evidence for regulators validating new AAM aircraft safety profiles.

4. Public confidence is fragile

AAM’s long-term growth depends on widespread consumer trust in safety. A single high-profile mechanical failure could stall market adoption for years. Conversely, transparent, validated health monitoring programs can serve as a marketing asset to reassure passengers, municipalities, and insurers.

Market growth snapshot: AHMS industry trajectory

The broader aircraft health monitoring systems market is already experiencing rapid growth, and AAM is poised to become a significant new contributor to that expansion.

- Global AHMS market size (2025):

- Estimated between $3.5B and $6.1B, depending on definitions and segmentation

- Projected market size (2034):

- Expected to reach between $10.9B and $7.4B, reflecting CAGRs between 6.5% and 8.0% depending onthe source.

- North America remains the largest market today (45% share), fueled by early adoption from major carriers, defense operators, and advanced R&D ecosystems.

- Asia-Pacific is the fastest-growing region, driven by urbanization, expanding aviation infrastructure, and AAM innovation hubs emerging in China, India, Japan, and Southeast Asia.

- Software-driven AHMS solutions are growing fastest, particularly in AI-powered analytics, machine learning predictive models, and integrated diagnostic dashboards that enable real-time decision support across entire fleets.

- AAM’s contribution to market growth will accelerate, as early commercial deployments of eVTOL, hybrid-electric regional aircraft, and autonomous delivery drones move from certification pilots into live urban deployments.

For AAM investors and operators, this signals both a growing supply chain of AHMS vendors—and a rising expectation that robust, AI-powered fleet health platforms will be fully operational by the time these aircraft start carrying paying passengers.

Aircraft health monitoring is the hidden driver of scalable AAM

Advanced Air Mobility is an exciting aviation innovation that must prove itself to regulators and win public trust. To scale beyond prototypes and early pilot routes, AAM operators will need to demonstrate the aircraft’s ability to predict, prevent, and respond to system failures long before passengers ever feel them.

These tools already exist. The commercial aviation sector has proven that aircraft health monitoring systems (AHMS), predictive maintenance platforms, and AI-powered diagnostics can measure performance and safety risks for fine-tuned handling and maintenance. The present AAM challenge is not inventing new technologies, but rather adapting them to the unique mechanical, structural, and working realities of electric, distributed, high-cycle urban flight.

AAM operators are turning to solutions like ePlaneAI. At ePlaneAI, we’re developing advanced AI-powered fleet health solutions purpose-built for the next generation of AAM aviation. While many other platforms are mere retrofits, ePalneAI’s platform is designed from the ground up to ingest live sensor streams, identify complex multivariable failure signatures, and deliver actionable alerts to operators before issues escalate into downtime.

Whether you’re scaling a regional eVTOL fleet or managing complex battery lifecycle models for hybrid powertrains or navigating supply-chain challenges, we help carriers make sense of their data for peak performance.

The future of AAM depends on public trust, operational consistency, and regulatory confidence. ePlaneAI delivers purpose-built predictive health monitoring to grow and flourish in flight’s new frontier, giving businesses the license to scale.

👉 Ready to see what true predictive fleet health can deliver for your advanced air mobility operation? Schedule a demo with ePlaneAI today.

Aviation Maintenance Trends That May Gain Momentum in Uncertain Circumstances

Aircraft are staying in service longer, supply chains are a powder keg, and the tech is evolving overnight. Discover the maintenance trends gaining momentum and what they mean for operators trying to stay airborne and profitable.

February 2, 2026

ePlane AI at Aircraft IT Americas 2026: Why Aviation‑Native AI Is Becoming the New Operational Advantage

The aviation industry is entering a new phase where operational performance depends not just on digital tools, but on intelligence.

October 2, 2025

Choosing the Right Aircraft Parts with Damage Tolerance Analysis

The future of aviation safety is all about the parts. Authentic, traceable parts bring optimal damage tolerance and performance to fleets for maximum safety and procurement efficiency.

September 30, 2025

How to Enter New Aviation Markets: The Complete Guide for Parts Suppliers

Breaking into new aviation markets? Learn how suppliers can analyze demand, manage PMA parts, and build airline trust. A complete guide for global growth.