AeroGenie — Your Intelligent Copilot.

Integrating Blockchain for Traceability in Aviation Maintenance

August 11, 2025

Blockchain is bringing crystal-clear traceability to aviation maintenance. It’s helping companies create tamper-proof records, track parts with confidence, and cut down on errors. See how the industry is using it today, and where blockchain is headed next.

The term blockchain is popping up everywhere, but its meaning is often misunderstood. When people hear the word blockchain, they often think of cryptocurrency, digital wallets, and the dark web.

In reality, however, blockchain is a secure digital system that is fundamentally reshaping how we store, share, and verify data, and it holds astonishing potential for the aviation industry.

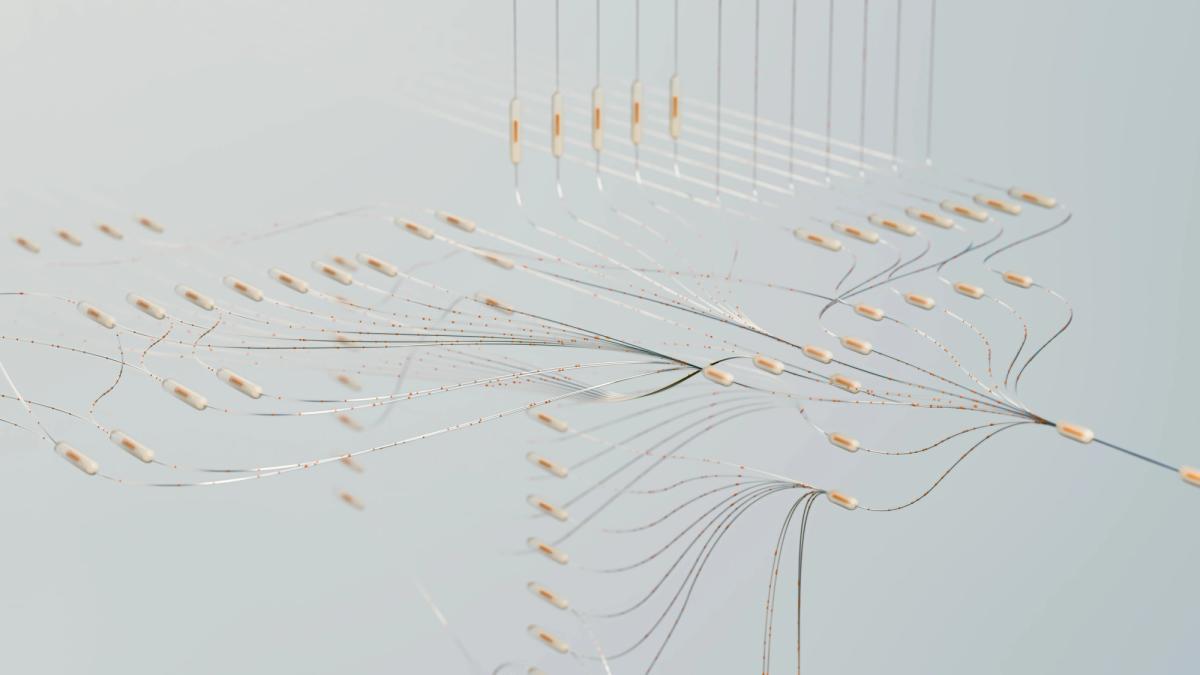

Blockchain is a decentralized digital ledger (shared peer-to-peer files) that records transactions across multiple systems in a secure way. These systems can include enterprise resource planning (ERP) systems, MRO software, inventory management platforms, digital twin platforms, and aircraft health monitoring tools.

The ledger is secure and tamper-proof. It works by grouping transactions into “blocks” and then chaining them together in chronological order. Once the data is entered into the ledger and verified, it cannot be removed or altered in any way. Entries provide a clear audit trail of all activity.

With ledgers unalterable (often referred to as “immutable”), blockchain is particularly well-suited for parts traceability. This is especially powerful for supply chain management (SCM)( and logistics, given that networks span continents and rely on countless sub-tier providers.

Within this void of data, blockchain could very well plug the gaps. McKinsey research has consistently found the technology’s “permanent” nature in recording data transactions to be ideal for managing a global supply network (McKinsey).

Beyond safe, unalterable storage, blockchain is also a powerful verification to ensure that the information it logs is accurate.

Each update to a blockchain is verified by computers called nodes that help run the network. These nodes agree on what gets added to the ledger, using rules like proof of work (like solving complex math problems) or proof of stake (ownership in the network as a form of commitment). This layered process keeps any one company or user from having full control.

Why traceability matters in supply chains

With goods regulated for quality and safety, companies need to know the full origin and journey of a product. While final manufacturing may be done safely and ethically at a local plant, a single aviation component could contain hundreds of parts from dozens of countries

This black box of potential safety gaps puts highly-regulated industries like aviation at constant safety risk. Companies must rely, often blindly, on a vast, global network to safely deliver well-made and properly stored products that meet quality and regulatory standards.

With traceability, companies can trace each part’s full journey at every stage of the supply chain. This enables companies to quickly identify and isolate defective batches, verify authenticity, reduce counterfeit risks, and meet requirements for safety, sustainability, and labor standards.

In traditional supply chains, without blockchain, the burden of full traceability cannot be met. Data is often limited, stuck in siloed systems, paper-based documentation, or inconsistent data formatting.

With blockchain, everything is recorded. From when and where raw material is processed to when it’s shipped to the end customer, every process, movement, and change of hands is recorded in a blockchain that all stakeholders can access in real-time.

This openness allows instant tracking and back-tracking of goods, critical for minimizing blind spots or accelerating response times in the event of recalls or other disruptions.

Why aviation maintenance needs a blockchain upgrade

The aerospace industry is one of the most strictly regulated industries in the world, with scrutiny intensifying in recent months. Maintenance logs, parts certifications, and traceability are required to prove airworthiness, yet many companies and MRO providers rely on dated tools (including pen and paper) and legacy software that was never built for today’s global complexity.

Fallout of this fragmented approach is on full display. In 2023, a scandal involving AOG Technics and alleged falsified parts documentation shook the industry, forcing airlines like United and Delta to ground dozens of aircraft for inspection.

In response, a coalition of major industry players, including Boeing, GE Aerospace, and American Airlines, formed the Aviation Supply Chain Integrity Coalition to improve traceability and guard against unapproved parts (Aviation Week).

Aviation parts are trickier than most, as they can change hands multiple times across the decades, moving among OEMs, leasing firms, airlines, independent MROs, and resellers.

Each transfer introduces a new opportunity for human error, incomplete records, or even fraud. CIMPA’s 2023 traceability white paper notes, “It is still very difficult to have a digital continuity from the aircraft OEM to the airline through the supply chain actors” due to inconsistencies in formats, standards, and IT capabilities (CIMPA White Paper).

An aviation blockchain directly addresses these shortcomings. By serving as a shared source of truth, it allows all authorized parties to access the same usage records, safe and unaltered, throughout a component’s lifecycle. This dramatically improves the reliability of records for inspections and airworthiness certifications, and is especially valuable for used or overhauled parts.

Let’s explore three current use cases for blockchain in aviation.

Use case 1: Part provenance and traceability

For aviation, blockchain’s most promising application may be in its creation of an immutable audit trail for parts, or what’s often referred to as “back-to-birth traceability.” Back-to-birth means having a complete, verifiable record of a part's history from its original manufacturing to its current configuration and usage.

This technology is already being used in aerospace. SkyThread for Parts, a blockchain-based platform developed by AFI KLM E&M and Parker Aerospace Group, is being used to trace hundreds of thousands of components in Boeing 787 aircraft (Aviation Week).

This is a major safety and cost-savings win, because missing or inaccurate records can result in quarantined parts, delayed repairs, and increasing costs. AFI KLM E&M reports that using SkyThread “significantly reduces the number of inbound quarantined parts,” which in turn streamlines maintenance and delivers smoother operations (Aviation Week).

Other aviation companies are using AI alongside blockchain to enhance part traceability. GA Telesis, for example, has partnered with Alitheon to integrate optical AI into its Wilbur platform.

The tool, called FeaturePrint, creates a “digital fingerprint” of each part using standard cameras and blockchain verification, thus removing the need for tags or labels that can be damaged or tampered with.

Alitheon claims that the odds of two FeaturePrints being identical are “one in a trillion,” making this a virtually fail-safe method for proving authenticity (Aviation Week).

Use case 2: Maintenance logs and lifecycle events

Blockchain can also log maintenance events across the entire aircraft lifecycle, capturing who performed what service, when, where, and under which conditions. These logs are a vital reference point for compliance, safety investigations, insurance audits, and eventual resale valuations.

Today, maintenance data is often stored in disconnected systems among OEMs, operators, and MRO providers. As a result, inconsistencies, delays, or missing records commonly arise, even though a single error can cost airlines millions in downtime.

A 2023 article in the International Journal of Production Economics argues that blockchain resolves these coordination issues by enabling “a single source of truth that synchronizes data in real time across all stakeholders in the maintenance value chain” (ScienceDirect: IJPE).

The aviation blockchain platform SkyThread for Parts includes automatic logging among its features, allowing frictionless capture of all part installations, repairs, and full service history. Every aircraft part carries its own maintenance log, and in a format that buyers, lessors, or regulators can easily access.

Stakeholders can trust the data, too. Blockchain’s ultra-secure design minimizes the risk of falsified entries, and smart contracts can be used to flag overdue services or verify technician credentials. (Frontiers).

Use case 3: Smart contracts for real-time verification

Smart contracts, self-executing code stored on the blockchain, offer a powerful way to enforce rules and automate actions without manual intervention.

In aviation MRO, they can ensure that specific conditions are met before a part is installed, a service is completed, or payment is released.

For example, a smart contract could verify that a component has passed required control tests and that the technician is certified before allowing it to be installed. Once all conditions are validated, the contract executes automatically, logging the event, updating inventory, and even releasing payment or notifying auditors.

This type of automation reduces delays, improves accountability, and minimizes the chance of error or fraud. As a 2023 study in Computers in Industry notes, “Smart contracts on blockchain reduce the need for intermediaries in verification tasks and enable autonomous trust-building mechanisms” (ScienceDirect: Computers in Industry).

The CIMPA Traceability White Paper highlights similar advantages, describing how blockchain and smart contracts “eliminate reconciliation issues and improve data reliability” across a product’s lifecycle (CIMPA White Paper).

In short, smart contracts reduce friction. Instead of chasing down approvals or digging through binders, maintenance teams and quality managers get instant validation based on transparent, permanently encoded rules.

Barriers to implementation

For all its promise, aviation blockchain has been slow to catch on. While the technology has penetrated the industry, major hurdles remain in place preventing wide-scale adoption.

Interoperability is one of the biggest challenges. Many stakeholders (OEMs, airlines, MRO providers, and government agencies) use different systems and formatting to manage records. For full blockchain integration, all actors in the supply chain would need to agree to, adopt, and integrate the same digital traceability methods (CIMPA White Paper).

Data privacy is another concern. Here, blockchain’s transparency is also its achille’s heel as aviation data contains highly sensitive information. There are challenges to deciding what gets recorded on-chain (public and shared) verus off-chain (private), and how to manage access permissions.

Companies must decide what gets recorded on-chain (public or shared) versus off-chain (private), and how to manage permissions. Many blockchain experts are calling for a hybrid solution that provides permissioned blockchain frameworks with selective data disclosure in a balance of transparency and privacy (Frontiers Energy Research).

Cost and scalability are also major factors. Transitioning from legacy systems to a blockchain-based architecture requires new technology, new workflows, and significant training.

Many small- and medium-sized enterprises lack the digital maturity, among other resources, to adopt blockchain. Large partners must lead the charge.

Lastly, there’s a skeptical regulatory environment. Authorities like the FAA and EASA must recognize blockchain records as legally valid for compliance audits and airworthiness certificates. Many organizations are cautious about investing in blockchain before regulatory go ahead, and will continue relying solely on decentralized technologies until then.

Industry momentum and pilot programs

Despite these setbacks, progress is happening—and quickly. Companies are increasingly launching pilot programs and forming consortia to experiment with blockchain for aviation traceability.

GA Telesis is one of the most visible early adopters. Their Wilbur parts provenance (tracing) platform combines Alitheon’s FeaturePrint technology (no-touch serialization), optical AI, and blockchain to create a fully digitized record of each part’s journey (Alitheon, Aviation Week).

Meanwhile, the deployment of SkyThread for Parts is continuing to scale. Initially used in its pilot phase to track Boeing 787 components, the platform is being adopted by other players like AJW Technique and L3 Harris (Aviation Week).

And early signals of regulatory interest are emerging. In anticipation of future approvals, the Aviation Supply Chain Integrity Coalition (ASCIC) is preparing. The ASCIC published a set of recommendations for parts traceability in its October 2024 report (Aviation Suppliers).

Among the report’s findings:

- Digital traceability is essential: ASCIC urges the adoption of uniform, digital standards of traceability.

- Minimum data standards needed: The coalition outlines foundational data elements (e.g., part number, serial number, OEM, maintenance records) that should accompany every part.

- Call for industry-wide adoption and collaboration: ASCIC recommends that all supply chain actors (lessors, OEMs, MROs, airlines, suppliers) implement consistent digital practices. No single organization can repair the traceability gap alone. Full adoption and coordination are required.

- Emerging technology as part of the solution: While technology-agnostic, the report points to blockchain and other secure digital technologies as key enablers of trust and transparency.

- Regulatory recognition is crucial: ASCIC emphasizes the need for regulatory bodies like the FAA and EASA to formally recognize digital traceability data as legally valid for compliance.

What it takes to scale blockchain in aviation maintenance

As ASCIC’s report outlines, it will take widespread collaboration for a new technology to move from pilot to production.

Building buy-in is the first obstacle, as blockchain only works if others adopt it. Successful adoption depends on trust and collaboration.

Next, organizations must agree upon data standards, including consistent definitions and data formats (JBSM).

Additionally, companies invest in the underlying infrastructure needed for blockchain technology, including both human and digital assets. This includes API connectors (for legacy systems), cloud-based blockchain nodes, smart contract libraries, and upskilling engineers and data managers.

Lastly, but perhaps most critically, there must be a clear incentive model. Stakeholders must see a measurable and defined benefit, such as reduced maintenance turnaround time (TAT), fewer grounded aircraft, or quicker and more streamlined regulatory audits. Larger, well-resourced people may need to shore up small players who lack the means to fund a technical infrastructure shift.

Early adopters in general are more likely to invest if they can see how blockchain will reduce the cost and complexity of traceability over time (CIMPA White Paper).

Moving ahead from traceability to intelligence

Blockchain’s capabilities for aviation don’t stop at traceability. It has the potential to become your operational hub for maintenance scheduling, repairs and records, parts lifecycles, and deep data analysis.

Paired with AI and machine learning, blockchain data can detect patterns, predict failures, and automate corrective actions. AI systems are already being used to identify parts most prone to defects, spot maintenance anomalies, and optimize spare parts inventory based on usage patterns.

Blockchain can also be combined with predictive analytics for more dynamic tasks such as scheduling repairs, inspections, and automatic reorders.

This dual approach also enables newer, more sophisticated models such as digital twin-enabled forecasting and performance-based logistics (PBL). But for this integrated approach to work, the models need accurate, reliable data at a massive scale—something blockchain is uniquely equipped to provide.

Researchers predict that blockchain will be a “foundational infrastructure” for the next generation of operational intelligence in aviation and other high-stakes industries (Frontiers).

Blockchain’s role in the future of aviation maintenance

Blockchain in aviation maintenance is already being actively tested, used, and refined in aviation to streamline parts traceability, maintenance log updates, and smart contract-driven compliance.

Initial pilot tests are showing promise. Blockchain can fill the gaps in traceability, trust, and coordination that legacy systems were never built to resolve.

But no matter how good aviation blockchain solutions get, success will hinge upon more than successful proofs of concept. For blockchain to work, it requires a full industry commitment with full aerospace participation, shared governance, and regulatory alignment.

Regulatory backing is trending more toward “when” than “if,” but there are no guarantees. Still, with heavy hitters like Boeing, GE, and Air France Industries are diving into blockchain-backed systems, future government buy-in seems likely. Full approval will likely hinge on resolving concerns around standardization, data privacy, and legal admissibility of digital records.

The momentum for blockchain traceability in aviation is here, but the industry as a whole will move cautiously. In the meantime, it’s smart to prepare for eventual approval. Even if regulators take longer than predicted, or don’t greenlight the technology in ways that industry leaders are hoping, your organization will still benefit. Closing visibility gaps, cleaning up fragmented data, and modernizing legacy workflows are major wins on their own.

Ready to take the first step toward smarter traceability?

ePlaneAI helps aviation organizations modernize supply chain visibility, regardless of where you are in your digital journey.

Let’s talk about what’s actually possible today —> Contact us.

Aviation Maintenance Trends That May Gain Momentum in Uncertain Circumstances

Aircraft are staying in service longer, supply chains are a powder keg, and the tech is evolving overnight. Discover the maintenance trends gaining momentum and what they mean for operators trying to stay airborne and profitable.

February 2, 2026

ePlane AI at Aircraft IT Americas 2026: Why Aviation‑Native AI Is Becoming the New Operational Advantage

The aviation industry is entering a new phase where operational performance depends not just on digital tools, but on intelligence.

October 2, 2025

Choosing the Right Aircraft Parts with Damage Tolerance Analysis

The future of aviation safety is all about the parts. Authentic, traceable parts bring optimal damage tolerance and performance to fleets for maximum safety and procurement efficiency.

September 30, 2025

How to Enter New Aviation Markets: The Complete Guide for Parts Suppliers

Breaking into new aviation markets? Learn how suppliers can analyze demand, manage PMA parts, and build airline trust. A complete guide for global growth.